Prefabricated wooden frame houses are made of different timber frames. The components of the house go through the prefabrication process in the production building and are brought to the site for fast assembly.

Advantages of Prefabricated Wooden Frame Houses

Fast and Easy Construction

The elements produced in the factory are completed fast and in large quantities – this significantly shortens the time of site works. Electricity, pipes, interior lining, windows and doors, and exterior boards are already attached to the elements of the wooden frame house produced in the factory according to the customer’s wishes and purposes. It usually takes 3-5 days to assemble the house. Then you can be sure that the house is waterproof. The more construction time you save, the lower the expected construction costs will be.

Energy Efficiency

Timber frame houses with properly selected materials have excellent insulation value and you can be sure that the house will be perfect for any climate. Timber frame houses retain heat, making it warmer inside for longer period, so there is no need to use heaters on colder days. In warm or hot seasons, wooden houses keep the interior cool. Therefore, the need for air conditioning is less. These qualities of wooden houses are very important in reducing energy consumption.

Longer Lifespan and Unchanging Property Value

A good timber frame house can last up to a century or even more. Because all elements are built in a dry, moisture-free and controlled environment, and with proper care, they are sure to last for many generations. This also affects the property value of the timber frame house unchanged, as it can be lived in for a long time.

Our main goal is to provide high-quality, economical house packages with customer-oriented service, using only materials produced under well-known trademarks. Our company highly values the speed and quality of the service provided to our customers.

EstHus Technology vs Environmental Factors

The main goal of EstHus in the construction of prefabricated wooden structures is to create passive houses that guarantee safety and living comfort for our customers. It is our responsibility to ensure that all our houses and buildings withstand the effects of the environment, so that every structure we build lasts as long as possible.

Therefore, with skilful planning and strict implementation, we carefully assemble layers of materials that effectively ensure the qualities of good wood construction listed hereunder.

Timber structures are renewable and have the ability to coexist with nature without posing any harmful threat to the environment. As wooden frames are easy to upgrade, nature is preserved and future generations are not threatened.

The timber frame elements are manufactured in a factory with quality control (compliance with ISO, ETA, PEFC and FSC® standards). The materials used are measured with moisture, strength class. All details are cut out with a machine that gives +/- 1 mm accuracy.

It has been proven that people living in wooden houses are healthier than people living in concrete houses. Timber houses have the ability to regulate and filter the air, allowing for fresh breathable air and a controlled temperature inside. We always recommend using natural wood-based insulation materials.

We strictly comply with legislation to achieve fire resistance. We ensure that all materials are well selected to achieve the best fire resistance and protection.

How EstHus passive houses work

Passive houses are considered the houses of the future. They promote energy efficiency and reduce the impact on the environment. They have the ability to sustain themselves naturally, so they only need a small amount of energy. This is one of the best ways to save Mother Nature. A passive house can be equivalent to the number of Earth hours the world observes. If one passive house can make a significant change in improving the ecosystem, how much more if most people offer the option of acquiring passive houses as their homes (such as timber frame houses)?

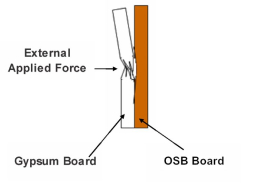

This illustration shows the basic function of OSB board, which makes each element strong when added as a membrane. It is systematically placed between the gypsum board and mineral wool insulation to prevent further damage due to external force. OSB board absorbs force and withstands impacts.

Advanced technology in the creation of prefabricated timber structures

Passive houses, also known as passive solar houses, are a type of highly energy efficient building design and construction that aims to minimize the need for external heating and cooling. The concept originated in Germany in the 1980s and has gained worldwide popularity as a sustainable and energy-efficient building standard. Passive houses work on the principles of maximising insulation, air tightness, ventilation and increasing sunlight.

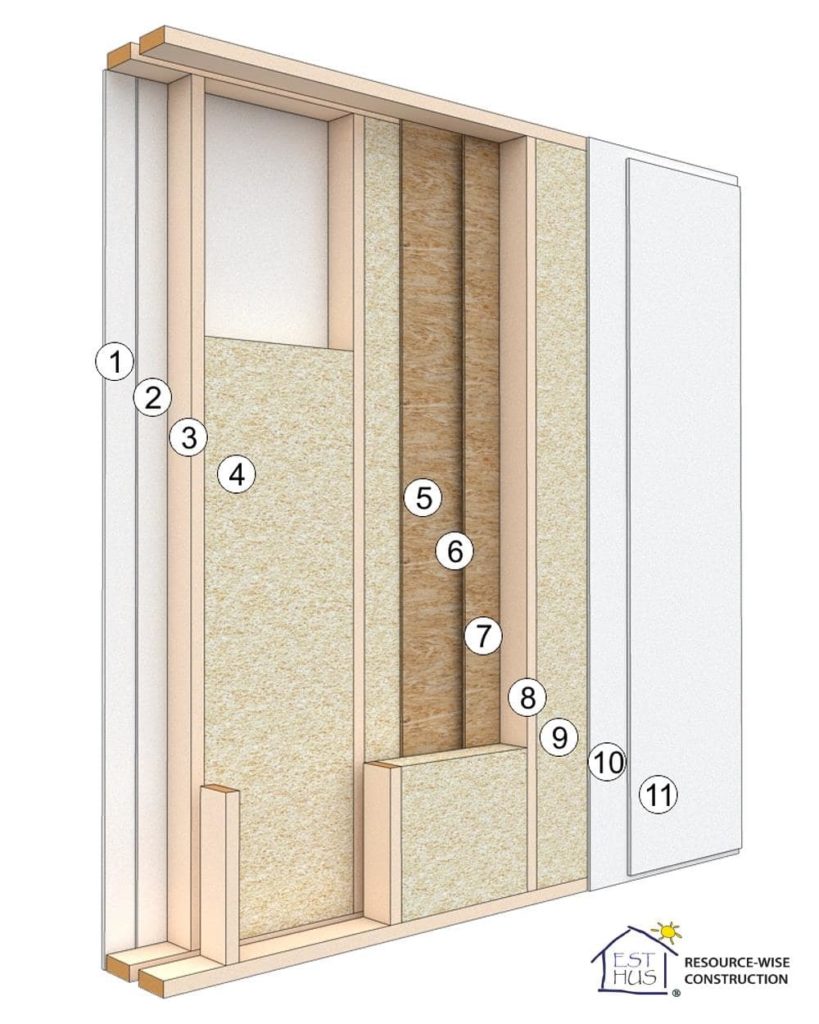

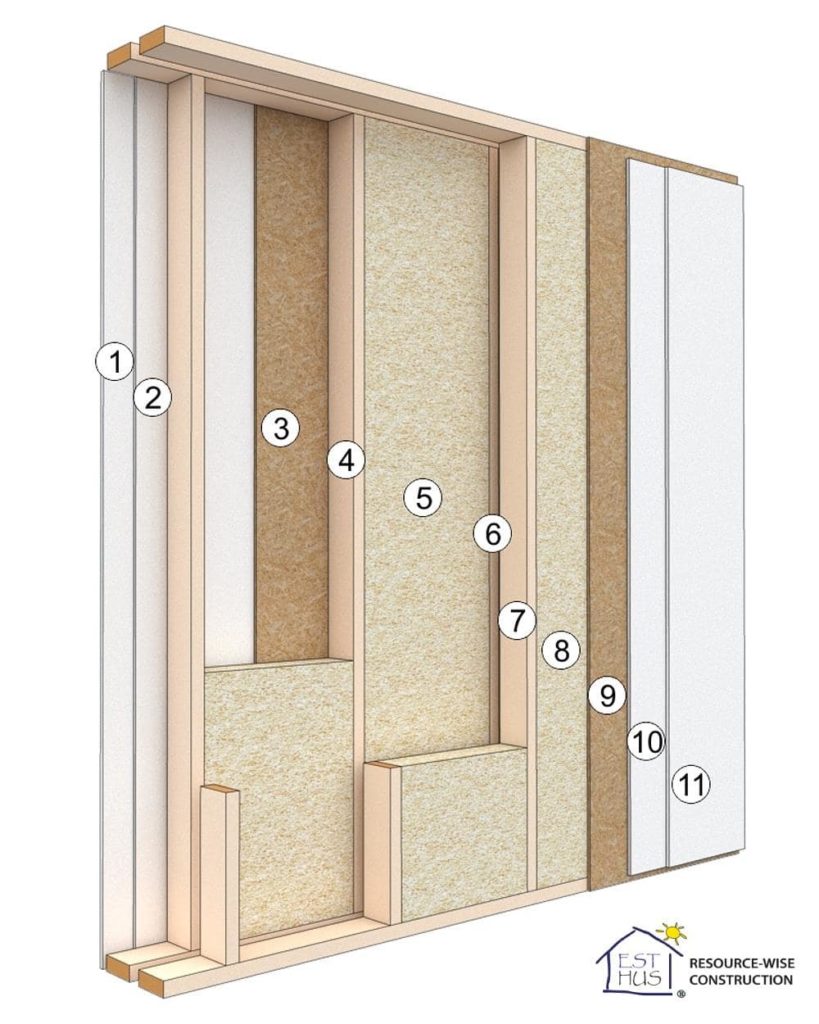

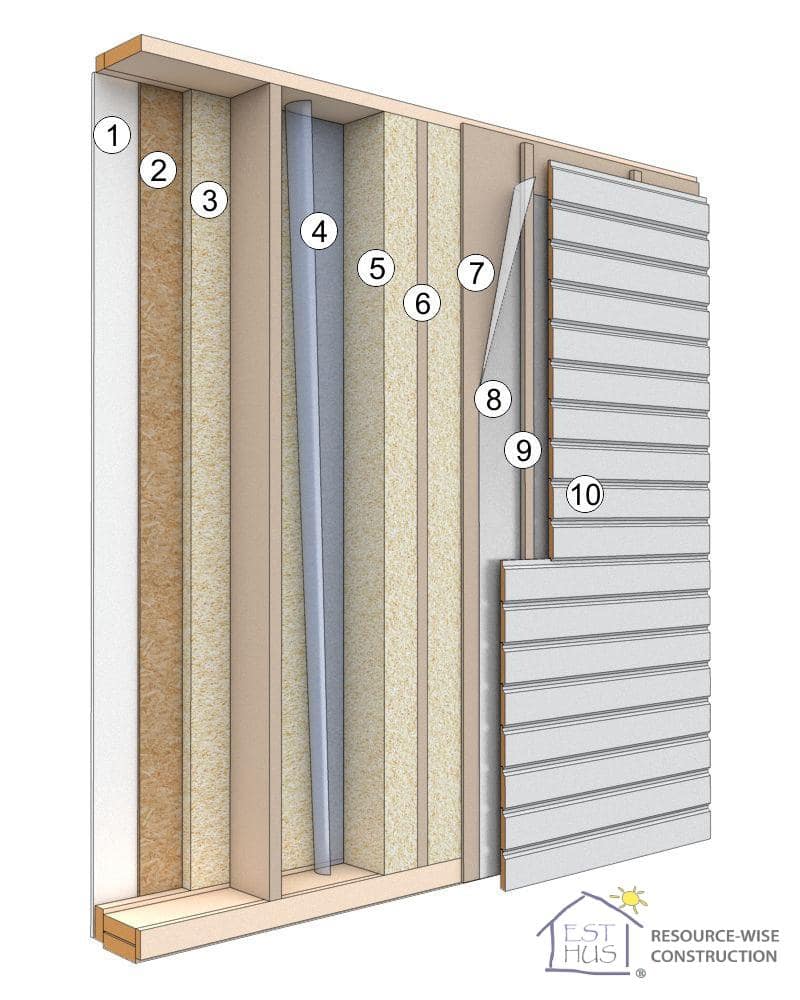

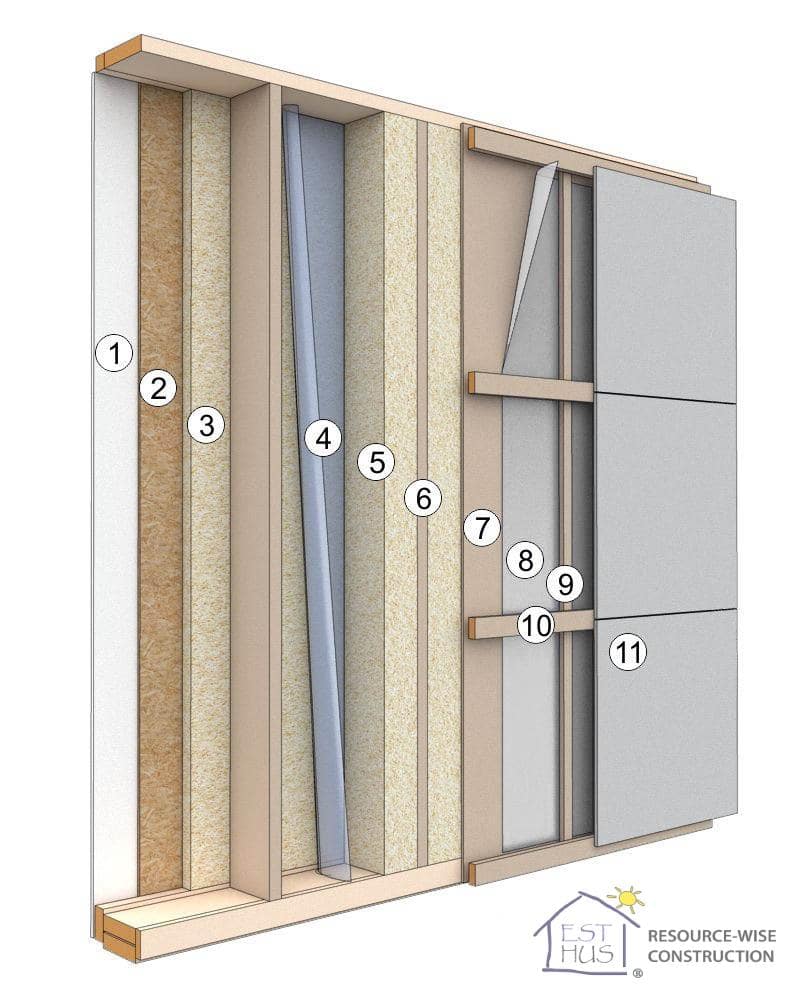

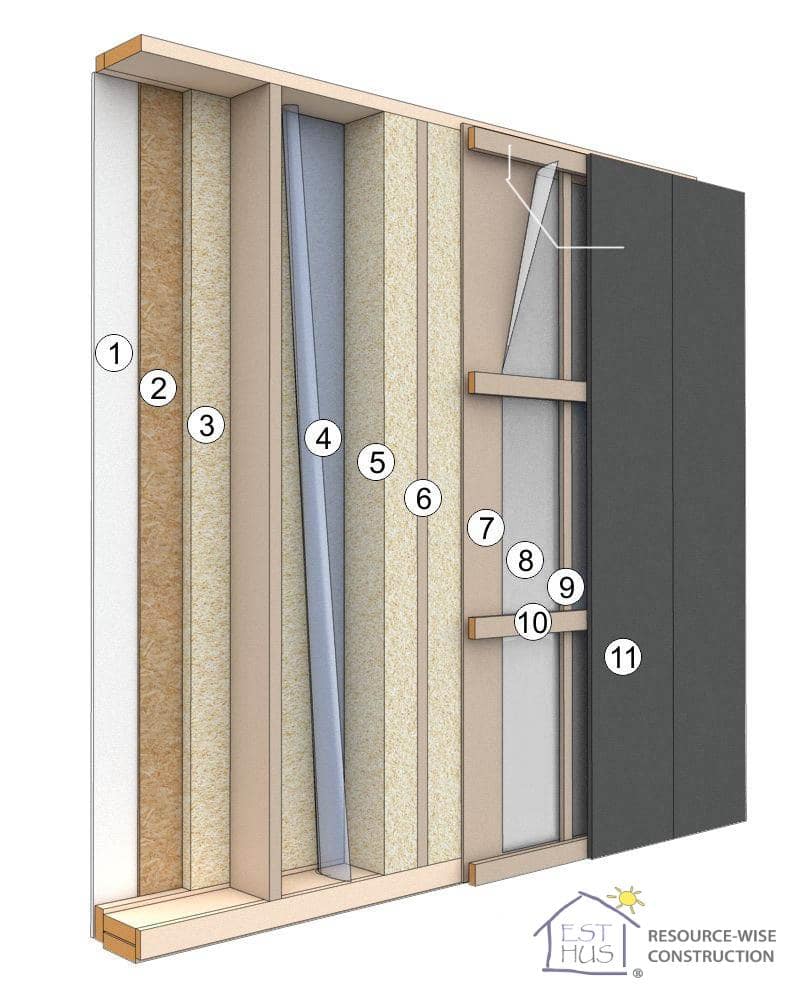

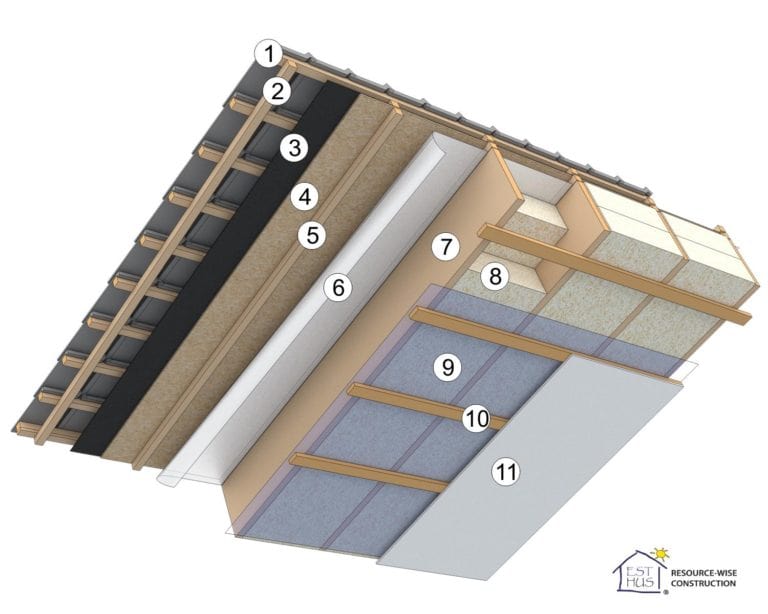

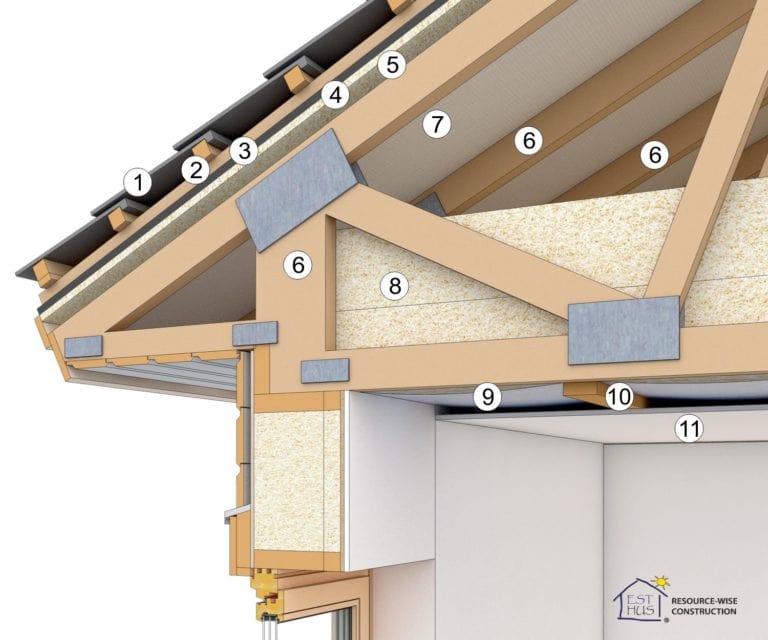

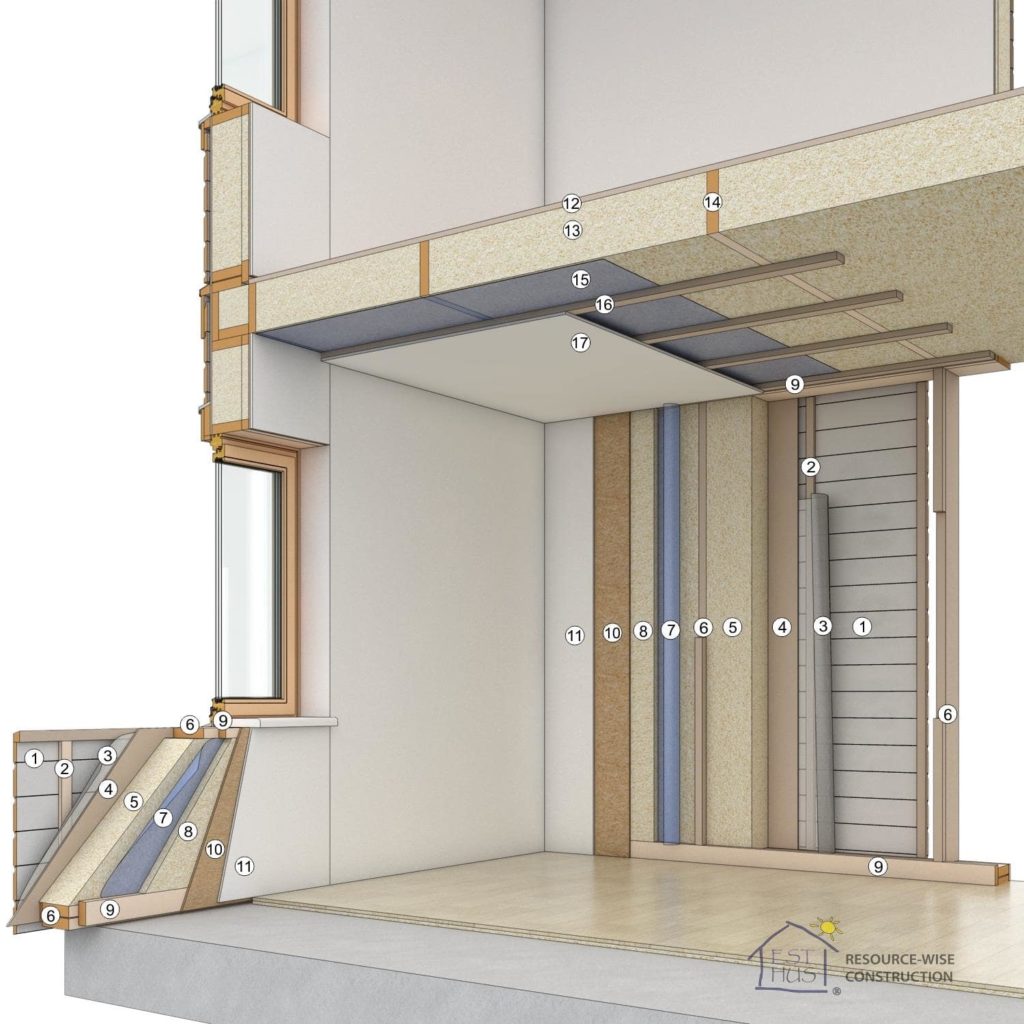

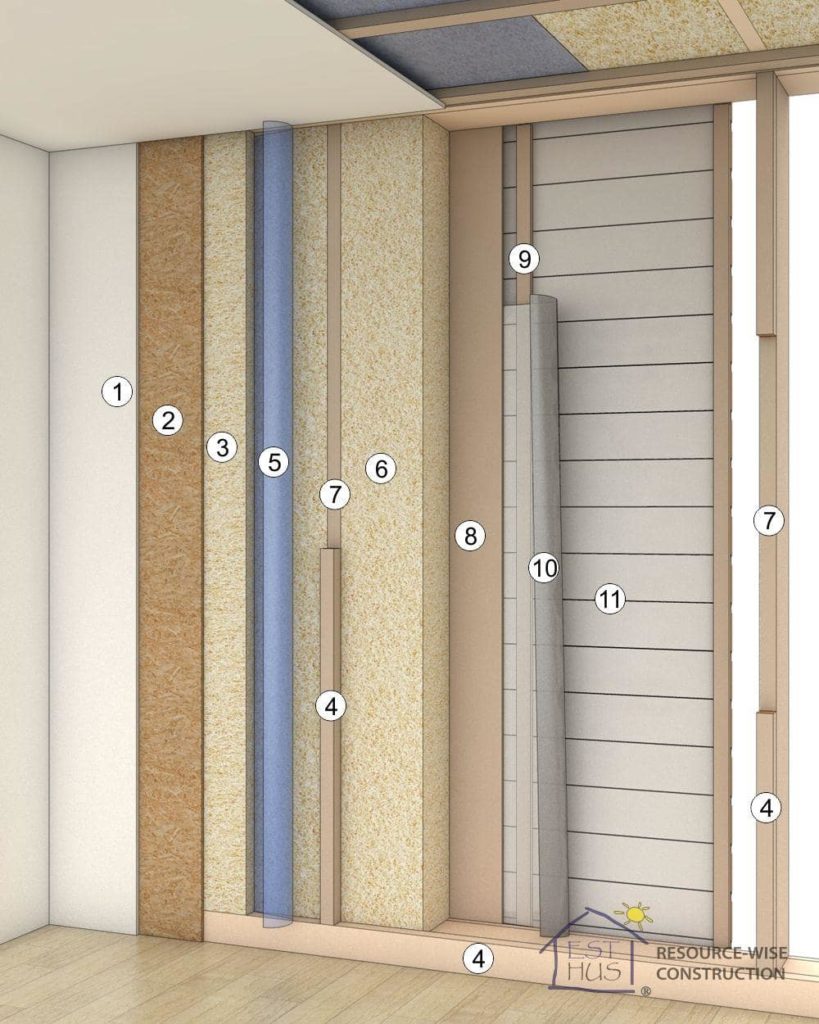

Below is an example of EstHus technology in creating prefabricated wall elements for all our standard designs. All the membranes or layers work together to form a strong and durable wall and the same goes for the roof, ceiling and floor.

With many years of experience in the production and installation of prefabricated timber frame houses, EstHus technology in this field has developed high-quality prefabricated timber structures all over Scandinavia. Our exceptional service represents the high level of professionalism and expertise of our staff and trusted partners.

Wood tends to shrink or expand when exposed to moisture and changing weather conditions. All lumber and timber used is kiln dried and planed before assembly. This is important to ensure that all the wood materials used in the construction of the elements move less when exposed to the outside during installation.

Internal walls act as partitions to form compartments within the house. The main materials for making internal walls depend on the purpose of the room they create. The internal walls can be produced in different thicknesses. It depends on static calculations, project requirements and customer wishes.

Below are the types of internal walls that are common in use.

In all types of duplexes, townhouses and apartment buildings, the walls between homes and apartments can be fireproofed. We recommend using Fermacell instead of gypsum, as it gives strength and rigidity to the building and makes the wall more soundproof.

EstHus supplies high-quality external wall systems and is constantly looking for ways to further improve them to achieve optimal functionality in terms of insulation, waterproofing, soundproofing, durability and strength. External walls must be tough and stable as they protect the house as a whole. All materials used in the manufacture of our external wall elements come from reliable partners and their quality is guaranteed both before manufacture and during the manufacture, transport and on-site installation of the elements.

We strongly recommend using natural wood-based insulation solutions. It is better for the environment, indoor climate and provides better heat protection.

Fermacell

In the production of Fermacell gypsum fiber boards, only natural materials are used exclusively, which is one of the factors in ensuring a healthy room climate. The plate is resistant to mechanical shocks, fireproof (A2 EN 13501-1 pcs from 30 min), sound-insulating, moisture-proof, bearing circle and stiffness plate. They ensure the stability and safety of a high-quality timber building.

Pro Clima

It is a type of construction film that is mainly used for waterproofing the outer layers of roof, ceiling, floor and wall elements. It is one of the key components of the walls and ceilings of prefabricated timber houses, as it protects the remaining materials from steam, air and soil gases that can penetrate them. It is commonly used after or between the installation of insulation materials. It lasts as long as other materials.

Wood-based insulation

Environmentally friendly wood fiber insulation protects against the cold, contributes to the moisture-technical performance of structures and increases the energy efficiency of buildings. Wood fiber materials have the highest heat capacity of the commercially available insulation materials. This makes them the best protection against the summer heat. Wood fiber insulation is rainproof, but at the same time has good water vapor permeability. They have good fire test properties and excellent sound insulation.

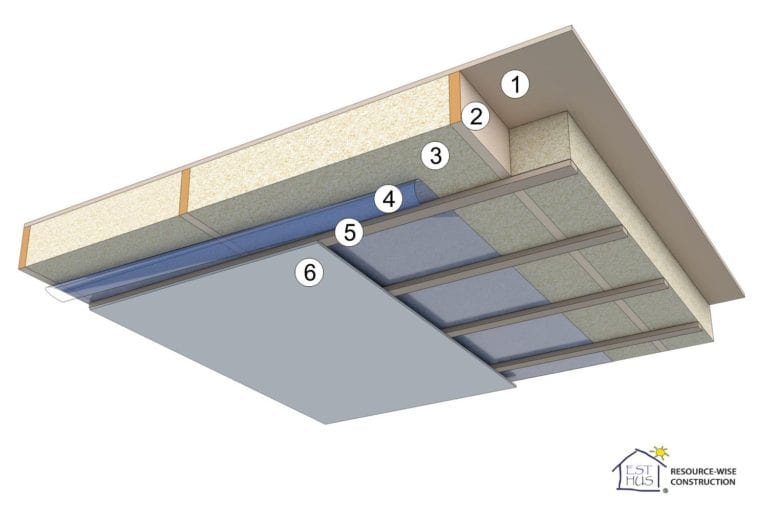

Ceiling and floor elements play a major role in the construction of prefabricated wooden frame houses. It is important that ceilings are heat resistant, as they are often exposed to heat during the day due to prolonged exposure to sunlight. Ceilings, which act as a floor at the same time, must be stable and durable and able to withstand heavy loads.

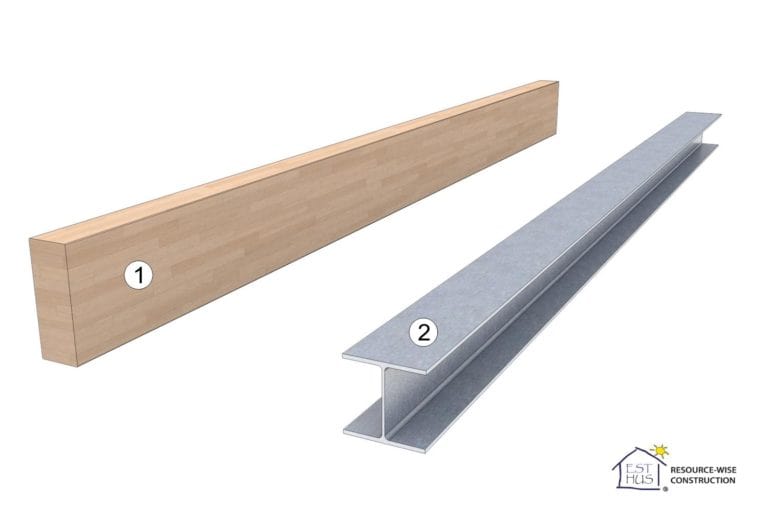

Glued laminated or metal beams can be used in ceilings. The size and modifications of the beams are selected by static calculation.

This illustration presents one of the many possible ceiling variants.

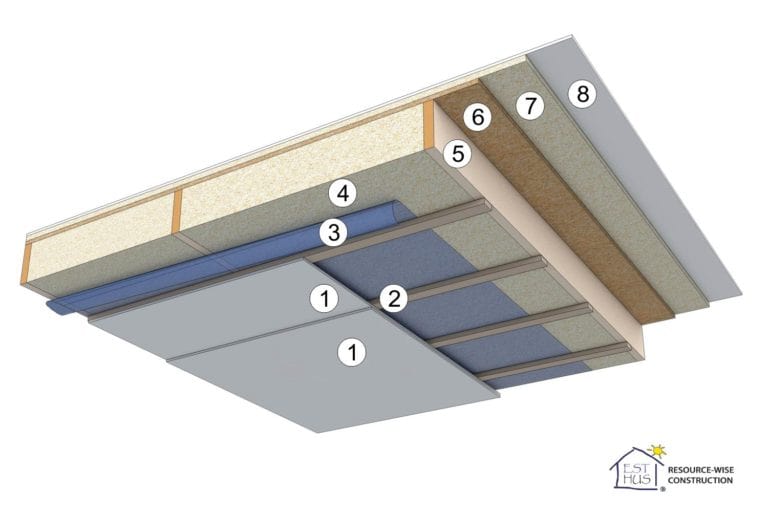

EstHus produces roofs as elements. All the high-quality materials we use in the manufacture of roof systems are guaranteed to be efficient and environmentally friendly.

It is recommended to use wood-based insulation for roof insulation, as it is rainproof, but at the same time has good water vapor permeability. They have good fire test properties and excellent sound insulation.

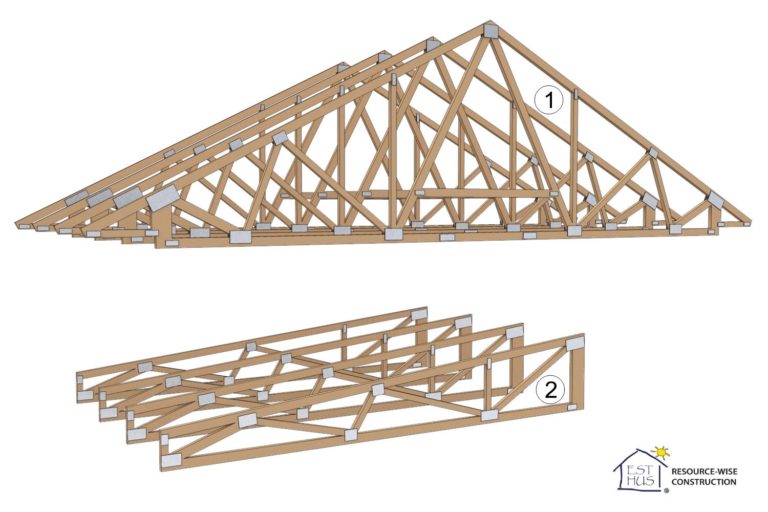

EstHus can also deliver wooden roof trusses. We have long-term cooperation partners who produce trusses for our houses.

Scandinavian houses typically use timber trusses, which are a composite of lumber designed to build frames that are fastened together with galvanized steel truss plates.

English

English