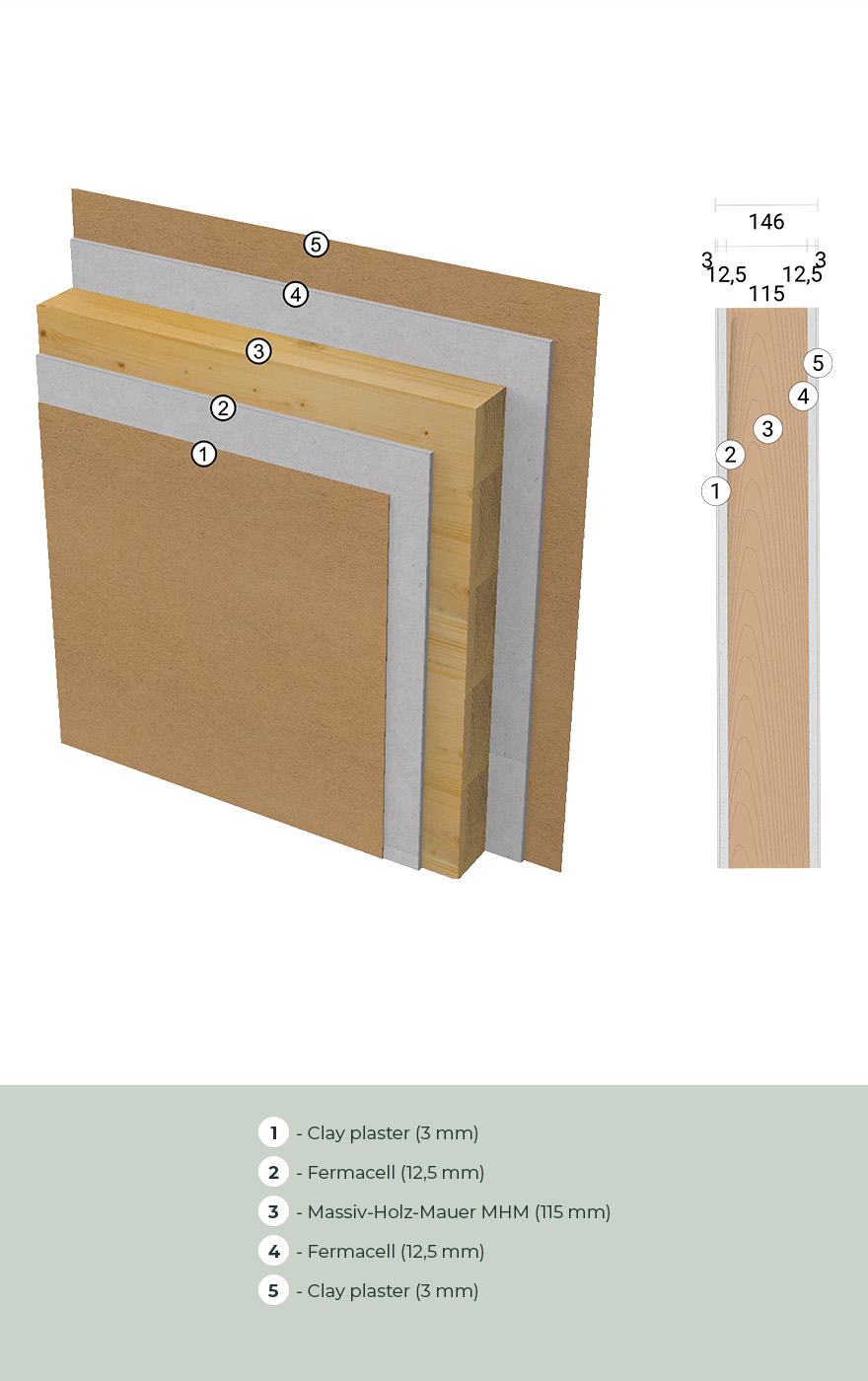

We also use only MHM construction in the interior walls. To add strength, stability and naturalness, we use gypsum fiberboard, which is one of the factors in ensuring a healthy indoor climate. For even better indoor climate we suggest to use clay or lime products. Clay and lime products are sustainable building materials with a small ecological footprint.

MHM® is a solid wood wall element that does not contain any films, glues, or chemicals, allowing for natural heat and moisture exchange to maintain a self-regulating indoor climate. The structure is very strong and durable, thanks to a simple yet ingenious solution. Cross-layered solid wood wall is produced with a special machine.

Massiv-Holz-Mauer® is made of high-quality softwood boards, which are produced by layering profiled boards on the substrate and connecting them with aluminum nails. Door and window openings are made in semi-finished wall elements with CNC processing, and all the necessary holes, grooves and cutouts for heating, sanitary equipment, electrical plugs and other devices are made with high-precision computer cutting.

MHM® offers more architectural possibilities than a log house, while maintaining a similar indoor climate.

- Natural living – without glue and chemicals

- Healthy interior climate for generations to come

- Tailored to your family

- Ecological and cozy – from basement ceiling to roof

The production process is divided into three steps:

The grooving of individual boards, the manufacture of individual wall plates and the so-called joint, which means the final finishing of the wall plate into a ready-to-install element with millimeter accuracy.

The dried boards are grooved which later forms a standing layer of air in the finished wall and consequently results in a better insulation value than with pure solid wood. Side-cuttings, which are left over from beam manufacturing form the basic material. The remarkable thing is that what used to be treated as a left-over now has its own value because this side-cutting is the raw material for the MHM® wall. Therefore, this is genuine “upcycling”.

The “wallmaster” produces raw wall elements from the profiled boards varying in size from 2 m x 2 m to 3.25 m x 6 m and in thicknesses of 11.5 cm to 34 cm, into which the boards are pressed cross-wise (lengthwise and crosswise) and connected with aluminum groove pins layer by layer. This ensures the highest possible degree of stability.

The raw wall element is moved to the CNC panel cutting machine standing in line, where the element is formatted in a third stage and the necessary door and window openings are cut. There is no more than +/- 2 mm tolerance. The drill holes for lifting slings, slots and recesses for heating and sanitary facilities, as well as electrical sockets and other installation preparations are milled into the element by computer-controlled tools.

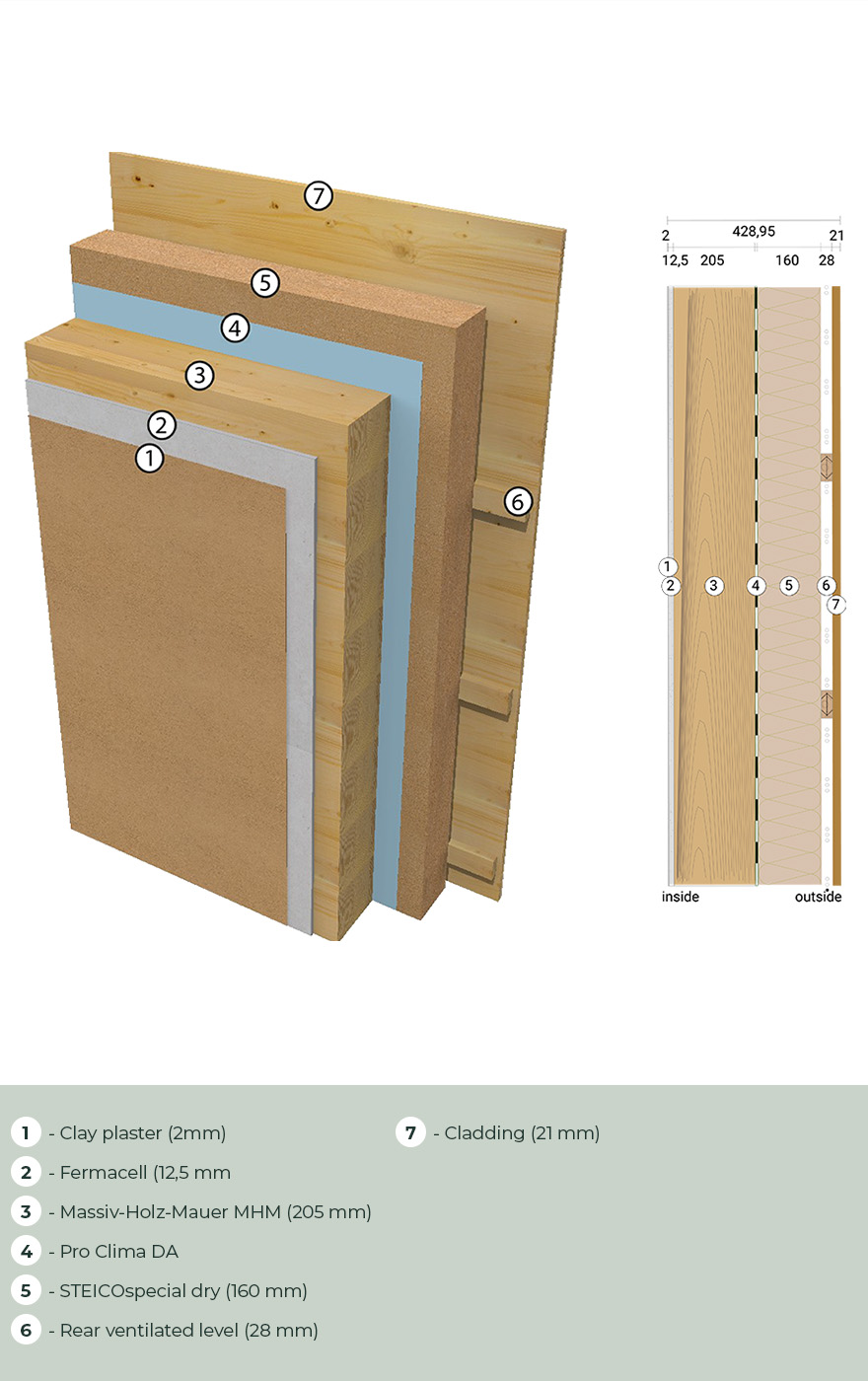

We have made recommended layers for construction on the external walls. This way the MHM and materials work together for heath indoor climate. External walls must protect you from cold, sun and rain. All selected materials work together to provide you a tough and stable home. These materials are free of chemicals and adhesive.

Massiv-Holz-Mauer® walls consist of untreated wood. The boards are connected with aluminium grooved pins, the resilience of which ensures extremely stable and strong wall elements. Thus, MHM® does not need glue as an adhesive. Due to this permeable construction method and the inherent properties of wood, MHM® walls do not require vapor retarders. Chemical wood protectors are generally not required in indoor wooden structures, as the drying process makes the wood dimensionally stable and resistant to parasites. On the exterior, constructive wood protection measures reduce the use of wood protection to a minimum. After installing the insulation elements, the facade of MHM® houses can be simply plastered.

While construction materials such as brick, steel and concrete mostly belong to the REI-30 fire resistance class, official measurements confirm that MHM® actually classed to the REI-90 class. Wood has another advantage: due to the material’s low thermal conductivity, heat does not reach neighbouring rooms so quickly. A fire can spread slowly while remaining controllable.

The strong construction of the Massiv-Holz-Mauer® walls and the resulting mass form a much larger heat store than in other construction systems. The thermal conductivity of wood is so low that the surface warms up quickly.

If the internal temperature drops, e.g. at night, the high retention capacity means that only the indoor air needs to be heated the next day, not the walls.

The MHM® wall stands out for its considerable insulation value. This is due to MHM’s unique construction method: the boards are cross-jointed and profiled with many small grooves that form an air cushion. These standing air layers give MHM® wall elements insulation values that are approximately 30% better than pure solid wood.

English

English